钻铤

关键词:

Kerwords:

钻铤

产品分类:

Category:

邮箱:

Email:

电话:

WhatsApp:

钻铤

钻铤采用AISI4145H铬钼钢制造,执行API规范及SY/T5144标准,可对螺纹进行冷滚压、镀铜或磷化处理,可加工双台肩螺纹及其它规格的特殊螺纹,可生产外径最大14英寸的钻铤。

● 标准尺寸、内径及螺纹

|

钻铤编号 Connection# |

外径OD |

内径ID |

长度mm Length |

台肩倒角直径D, mm |

弯曲强度比 Bending strength ratio |

||

|

mm |

in |

mm |

in |

||||

|

NC23-31 |

794 |

31/8 |

31.8 |

11/4 |

9150 |

76.2 |

2.57:1 |

|

NC26-35 |

88.9 |

31/2 |

38.1 |

11/2 |

9150 |

82.9 |

2.42:1 |

|

NC31-41 |

104.8 |

41/8 |

50.8 |

2 |

9150或9450 |

100.4 |

2.43:1 |

|

NC35-47 |

120.7 |

43/4 |

50.8 |

2 |

9150或9450 |

114.7 |

2.58:1 |

|

NC38-50 |

127.0 |

5 |

57.2 |

21/4 |

9150或9450 |

121.0 |

2.38:1 |

|

NC44-60 |

152.4 |

6 |

57.2 |

21/4 |

9150或9450 |

144.5 |

2.49:1 |

|

NC44-60 |

152.4 |

6 |

71.4 |

213/16 |

9150或9450 |

144.5 |

2.84:1 |

|

NC44-62 |

158.8 |

61/4 |

57.2 |

21/4 |

9150或9450 |

149.2 |

2.91:1 |

|

NC46-62 |

158.8 |

61/4 |

71.4 |

213/16 |

9150或9450 |

150.0 |

2.63:1 |

|

NC46-65 |

165.1 |

61/2 |

57.2 |

21/4 |

9150或9450 |

154.8 |

2.76:1 |

|

NC46-65 |

165.1 |

61/2 |

71.4 |

213/16 |

9150或9450 |

154.8 |

3.05:1 |

|

NC46-67 |

171.4 |

63/4 |

57.2 |

21/4 |

9150或9450 |

159.5 |

3.18:1 |

|

NC50-67 |

171.4 |

63/4 |

71.4 |

213/16 |

9150或9450 |

159.5 |

2.37:1 |

|

NC50-70 |

177.8 |

7 |

57.2 |

21/4 |

9150或9450 |

164.7 |

2.54:1 |

|

NC50-70 |

177.8 |

7 |

71.4 |

213/16 |

9150或9450 |

164.7 |

2.73:1 |

|

NC50-72 |

184.2 |

71/4 |

71.4 |

213/16 |

9150或9450 |

169.5 |

3.12:1 |

|

NC56-77 |

196.8 |

73/4 |

71.4 |

213/16 |

9150或9450 |

185.3 |

2.70:1 |

|

NC56-80 |

203.2 |

8 |

71.4 |

213/16 |

9150或9450 |

190.1 |

3.02:1 |

|

65/8REG |

208.6 |

81/4 |

71.4 |

213/16 |

9150或9450 |

195.7 |

2.93:1 |

|

NC61-90 |

228.6 |

9 |

71.4 |

213/16 |

9150或9450 |

212.7 |

3.17:1 |

|

75/8REG |

241.3 |

91/2 |

76.2 |

3 |

9150或9450 |

223.8 |

2.81:1 |

|

NC70-97 |

247.6 |

93/4 |

76.2 |

3 |

9150或9450 |

232.6 |

2.57:1 |

|

NC70-100 |

254.0 |

10 |

76.2 |

3 |

9150或9450 |

237.3 |

2.81:1 |

|

85/8REG |

279.4 |

11 |

76.2 |

3 |

9150或9450 |

266.7 |

2.84;1 |

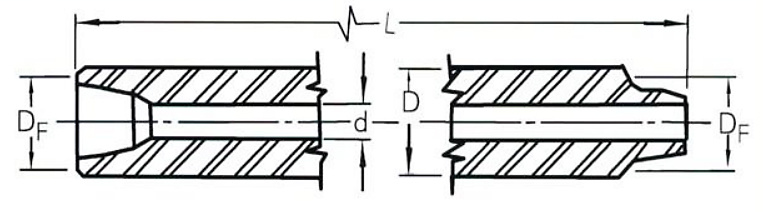

吊卡槽和卡瓦槽

根据用户需要,可在钻铤上加工满足API规范要求的吊卡槽、卡瓦槽结构。

钻铤吊卡槽、卡瓦槽尺寸

|

钻铤外径 OD |

吊卡槽深度 LE±0.2 |

R1C |

角度 αb |

卡挖槽深度 LS±0.4 |

角度 βb |

|

101.6-117.5 |

5.6 |

3.2+0.4 |

4° |

4.8 |

3.5° |

|

120.6-142.9 |

6.4 |

3.2+0.4 |

5° |

4.8 |

3.5° |

|

146.0-168.3 |

7.9 |

3.2+0.4 |

6° |

6.4 |

5° |

|

171.4-219.1 |

9.5 |

4.8+0.8 |

7.5° |

6.4 |

5° |

|

≥222.2 |

11.1 |

6.4+0.8 |

9° |

6.4 |

5° |

钻铤的力学性能

|

外径范围OD |

屈服强度 σ0.2 Mpa |

就控强度 σb Mpa |

伸长率 δ4 % |

布氏硬度 |

夏比冲击动 AK J |

|

|

mm |

in |

|||||

|

79.4~174.6 |

31/8-63/4 |

≥758 |

≥965 |

≥13 |

≥285 |

≥54 |

|

177.8~279.4 |

7~11 |

≥689 |

≥931 |

|||

钻铤的主要公差尺寸

|

外径范围OD |

外径OD |

内径ID |

长度 |

台角倒角直径 | |

|

mm |

in |

||||

|

≤88.9 |

≤31/2 |

+1.2 0 |

+1.6 0 |

+152.4 |

40.4 |

|

>88.9~114.3 |

>31/2~41/2 |

+1.6 0 |

|||

|

>114.3~139.7 |

>41/2~51/2 |

+2.0 0 |

|||

|

>139.7~165.1 |

>51/2~61/2 |

+3.2 0 |

|||

|

>165.1~215.9 |

>61/2~81/2 |

+4.0 0 |

|||

|

>215.9~241.3 |

>81/2~91/2 |

+4.8 0 |

|||

|

>241.3 |

>91/2 |

+6.4 0 |

|||

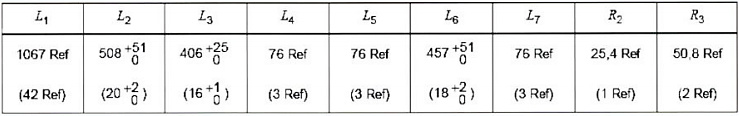

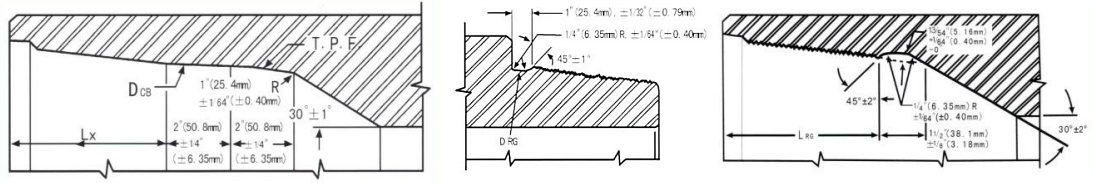

钻铤螺纹连接部位应力分散槽

|

螺纹类型 |

内螺纹台肩面至最后 一牙刻痕长度 LX ±1.59 mm |

内螺纹圆柱段 直径 Dcb +0.40 -0 mm |

内螺纹圆柱段 后的锥孔锥度 ±20.83 mm/m |

外螺纹槽 直径 DRC +0 -0.79 mm |

可替代内螺纹台肩面 至应力分散槽长度 LRG +0 -3.18 mm |

|

NC35 |

82.6 |

82.15 |

166.67 |

82.15 |

85.73 |

|

NC38 |

88.9 |

88.11 |

166.67 |

89.10 |

92.08 |

|

NC40 |

101.6 |

92.87 |

166.67 |

95.81 |

104.78 |

|

NC44 |

101.6 |

101.60 |

166.67 |

106.36 |

104.78 |

|

NC46 |

101.6 |

106.76 |

166.67 |

109.93 |

104.78 |

|

NC50 |

101.6 |

117.48 |

166.67 |

120.45 |

104.78 |

|

NC56 |

114.3 |

121.84 |

250.00 |

134.04 |

117.48 |

|

NC61 |

127.0 |

132.95 |

250.00 |

148.31 |

130.18 |

|

NC70 |

139.7 |

152.00 |

250.00 |

170.54 |

142.88 |

|

NC77 |

152.4 |

166.29 |

250.00 |

188.01 |

155.58 |

|

65/8REG |

114.3 |

134.14 |

166.67 |

137.59 |

117.48 |

|

75/8REG |

120.7 |

148.83 |

250.00 |

161.26 |

123.83 |

|

85/8REG |

123.8 |

172.24 |

250.00 |

185.45 |

127.00 |

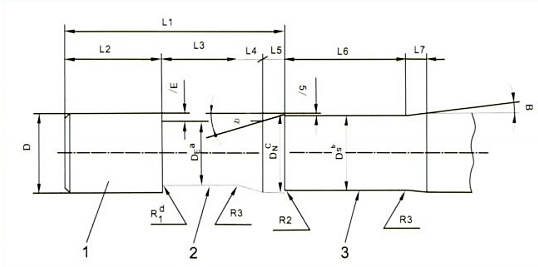

内螺纹背孔式应力分散槽 / 外螺纹应力分散槽 / 替代的内螺纹应力分散槽

在线留言

ONLINE CONSULT